100% Quality Guarantee on All Fittings! Free samples delivery.

Latrolet Fitting

Latrolet is widely used abroad in recent years, It is used to connect the reinforced fittings. As it is reliable, cheap, simple, good for flow, seriation, standardization, and choose easily. The body of outlets is made in excellent Forgings. The material is the same as pipes. We can make latrolet from Carbon steel, Alloy steel, Stainless steel, etc.

1.What is Latrolet?

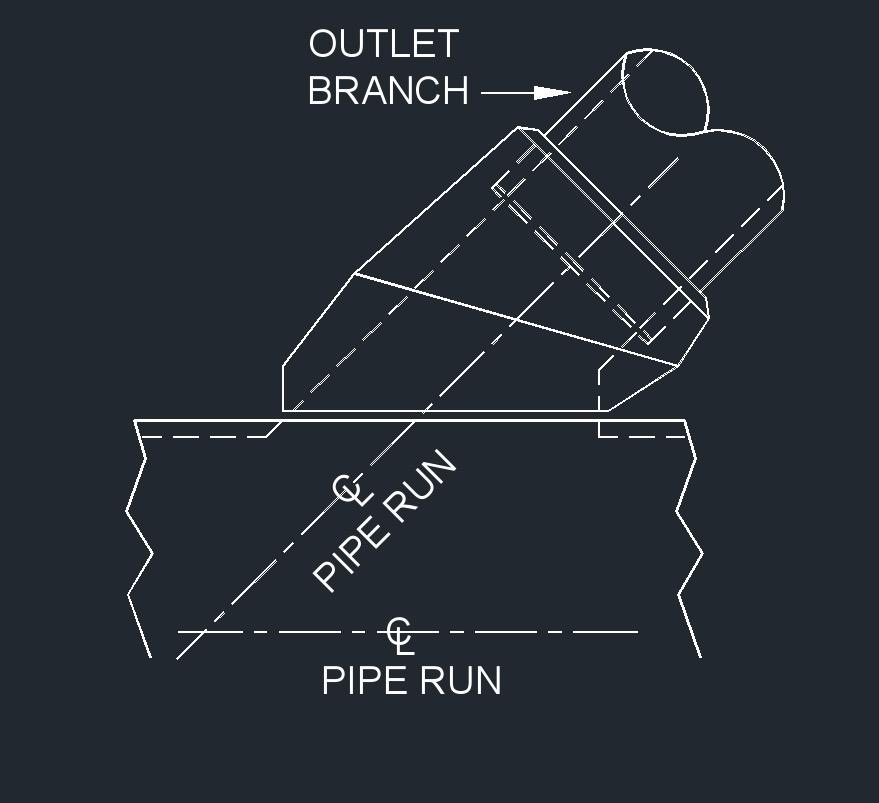

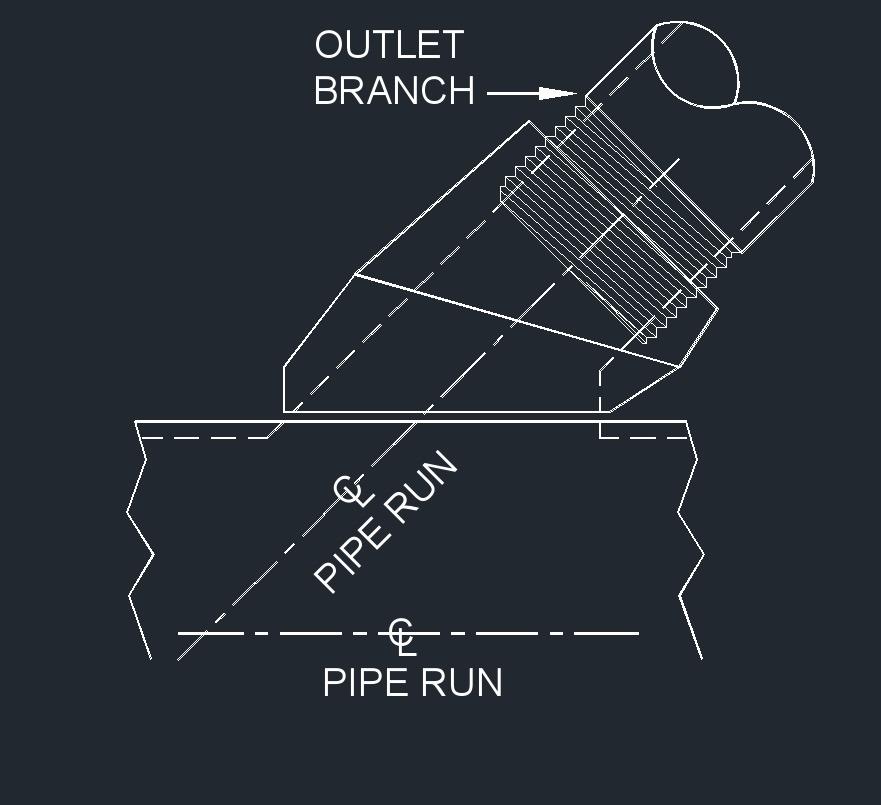

LATROLET, used for taking branch which comes in a 45°or any other special degree as required by customer. End connections of a Latrolet are available butt-weld to meet specific reinforcement requirements, and 3000# or 6000# classes for Socket Weld and threaded applications.

Features of Lateral Outlets:

- Abrasion resistance

- Durability

- Dimensional accuracy

- High performance

- Low Maintenance

- Long Service Life

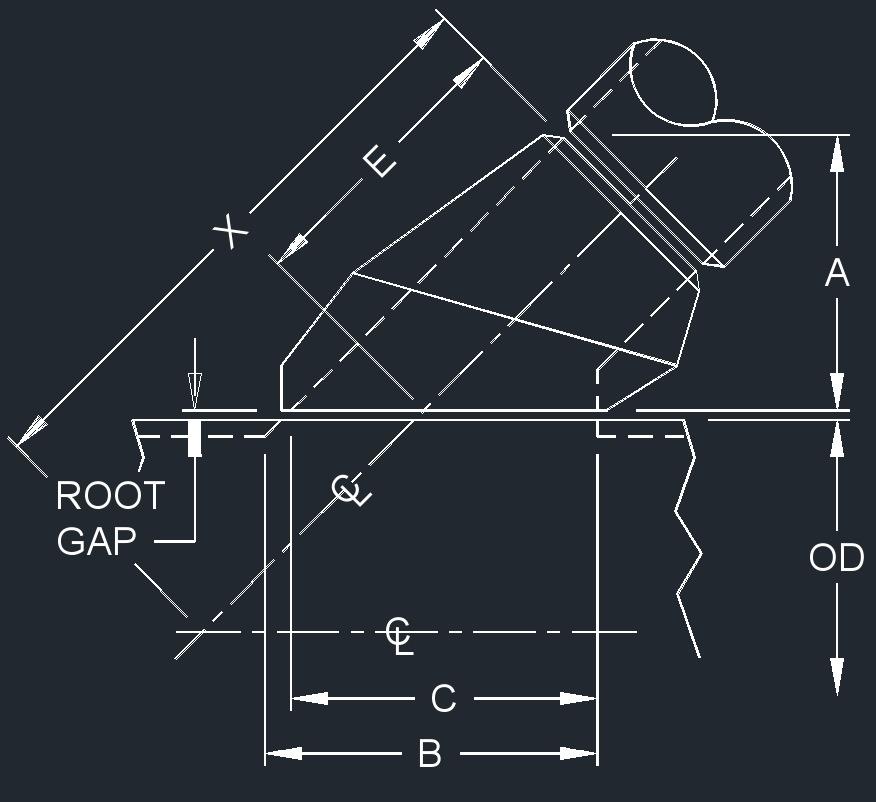

Class 3000 Threaded Latrolet Dimensions and Socket Weld Latrolet Dimensions

Class 3000 Threaded and Socket Weld Latrolet | ||||

Size | A | B | C | E |

1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

1/2 | 39.69 | 59.53 | 36.51 | 39.69 |

3/4 | 47.63 | 69.85 | 44.45 | 48.42 |

1 | 55.56 | 82.55 | 53.98 | 55.56 |

1 1/4 | 63.50 | 97.63 | 66.68 | 74.61 |

1 1/2 | 69.85 | 107.16 | 76.99 | 66.68 |

2 | 85.73 | 138.11 | 104.78 | 80.17 |

Class 6000 Threaded Latrolet Dimensions and Socket Weld Latrolet Dimensions

| Class 6000 Threaded and Socket Weld Latrolet | ||||

|---|---|---|---|---|

| Size | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 47.63 | 69.85 | 44.45 | 48.42 |

| 3/4 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1 | 63.50 | 92.87 | 66.68 | 62.71 |

| 1 1/4 | 69.85 | 107.16 | 76.99 | 66.68 |

| 1 1/2 | 85.73 | 138.11 | 104.78 | 80.17 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

Butt weld Latrolet Dimensions-Standard & XS Butt Weld

Standard & XS Butt Weld Latrolet | ||||

Size | A | B | C | E |

1/4 | 33.34 | 53.18 | 36.51 | 39.69 |

3/8 | 33.34 | 53.18 | 36.51 | 39.69 |

1/2 | 34.93 | 54.77 | 36.51 | 39.69 |

3/4 | 42.86 | 64.29 | 44.45 | 48.42 |

1 | 50.01 | 76.20 | 53.98 | 55.56 |

1 1/4 | 57.94 | 91.28 | 66.68 | 62.71 |

1 1/2 | 62.71 | 100.81 | 76.99 | 66.68 |

2 | 80.96 | 133.35 | 104.78 | 86.52 |

2 1/2 | 80.17 | 131.76 | 104.78 | 80.17 |

3 | 96.84 | 158.75 | 126.21 | 96.04 |

4 | 120.65 | 198.44 | 163.51 | 115.89 |

Butt weld Latrolet Dimensions-Sch. 160 and XXS Butt Weld

Sch. 160 and XXS Butt Weld Latrolet | |||

Size | A | B | C |

1/4 | 39.69 | 58.74 | 36.51 |

3/8 | 39.69 | 58.74 | 36.51 |

1/2 | 46.04 | 69.85 | 44.45 |

3/4 | 53.98 | 82.55 | 53.98 |

1 | 63.50 | 96.84 | 66.68 |

1 1/4 | 69.85 | 107.95 | 76.20 |

1 1/2 | 85.73 | 136.53 | 104.78 |

- Class 3000 – for use with Sch. 80 pipe.

- Class 6000 – for use with Sch. 160 pipe.

- Dimensions and tolerances in accordance with ANSI/ASME B16.9, ANSI/ASME B16.25 and MSS SP-97.

- Dimensions and tolerances in accordance with ANSI/ASME B16.11

- Specifications for carbon steel forgings in accordance with ASTM A105

- Threads in accordance with ANSI/ASME B1.20.1

3. Latrolet Material Grade

- Stainless Steel Latrolet – SS Lateral Outlets

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L - Duplex Steel Latrolet

ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F 61 - Alloy Steel Latrolet – AS Lateral Outlets

ASTM / ASME A/SA 182 F1, F5, F9, F11, F12, F22, F91 - Carbon Steel Latrolet – CS Lateral Outlets

ASTMA 105/A694/ Gr. F42, 46, 52, 56, 60, 65, 70 - Low Temperature Carbon Steel Latrolet – LTCS Lateral Outlets

A350 LF3/A350 LF2

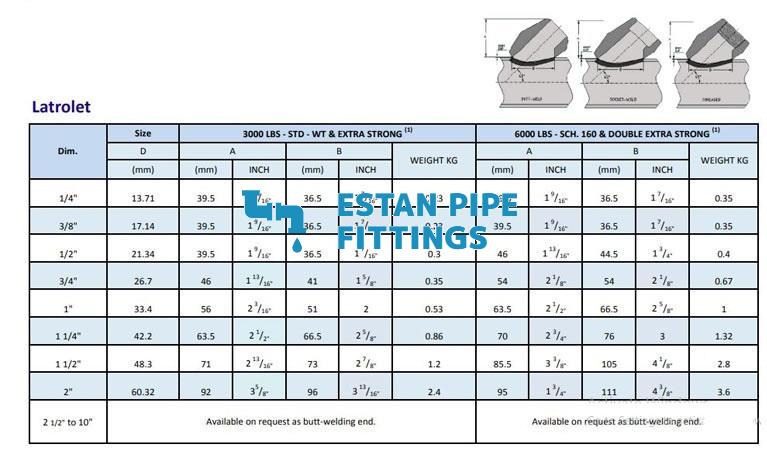

4. Latrolet Weight

5. Latrolet Marking and Packaging

- Marked Latrolet fittings with Size, Pressure, Grade, Standard, and Heat No.

- All Latrolet fittings are surfaced with oil before packing.

- Sleeved forged steel Latrolet fittings into plastic bags individually.

- Packed them in cartons and wooden cases, then bundled packages with nylon rope.

- Clear labels are tagged on the outside of the package for easy identification of the quantity and product. Great care is taken during operation and transportation.

6. Latrolet Test Certificates

At Estan pipe fittings, all olets fittings are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report.

- Specify Size

Header run pipe size

Branch pipe size - Specify Style

Socket weld latrolet, theaded latroelt, butt weld latrolet - Indicate Class or Schedule

Class 3000 or 6000 – Threaded or Socket latrolet

STD, XS, Sch 160/XXS, ect– Buttweld latrolet - Specify Material

Stainless Steel Latrolet

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Duplex Steel Latrolet

ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F 61

Alloy Steel Latrolet

ASTM / ASME A/SA 182 F1, F5, F9, F11, F12, F22, F91

Carbon Steel Latrolet

ASTMA 105/A694/ Gr. F42, 46, 52, 56, 60, 65, 70

Low Temperature Carbon Steel Latrolet

A350 LF3/A350 LF2

Check our latest products