100% Quality Guarantee on All Fittings! Free samples delivery.

Types of Branch Fittings

Branch Fittings (otherwise called Olet pipe fittings or Outlet fittings) will be fittings that give an outlet from a bigger pipe to a smaller one (or one of a similar size). Making a branch connection in the run pipe is useful in many ways to avoid complex networks.

- Distribution of fluid up to the different columns, vessels, storage tanks, Pumps, and Exchangers.

- Reducing the cost of fittings used for taking branches from the run pipe.

- For Provision of drain and vent for hydro test purposes.

- Accumulation of fluid pumped from different pumps to generate pressure.

- For installing instrument connection on header pipe.

Pipe branch fittings are used to create integrally reinforced connections from a run pipe (header pipe) to an outlet pipe, at 45 or 90 degrees, alternatively to connections made with buttweld tees, reinforcing pads, and saddles. This type of forged fittings are otherwise called “branch connections”, or “branch fittings”, or “pipe branch outlet fittings” or, simply, “Olets”.

Estan pipe fittings meet the 100% reinforcement requirement of applicable piping codes i.e. ASME B31.1, B31.3, B31.4, and B31.8. We also meet the MSS-SP-97 Standard- Integrally Reinforced Forged Branch Outlet Fittings.

Olet fittings are available in different sizes of branch outlet sizes. This is basically a self-reinforced fitting that has sufficient capacity to handle stress and pressure developed in pipes. Types of Olets fittings frequently used are:

Weldolet is one of the most common branch connections available and is considered a butt-weld fitting due to its design ( weldolet ends are beveled types). This style of olet is used in high-temperature and high-pressure conditions.

Weldolet makes a 90° branch connection and – comes in full size or reducing for a straight piece of pipe. A weldolet is designated by the run length by the branch length. For example, a 6-inch weldolet on a 12-inch pipe would be a 12×6 Weldolet.

- END – Bevel end

- Branch Pipe End – Bevel end

- Size Range – 2” – 24”

- Most commonly size range used in the industry – 2” – 8”, (economical size range)

- Thickness/Schedule – same as the pipe

Sockolet is the same as weldolet but with socket end as per ASME B16.11. A socket in which the pipe can sit to make welding and installation easier. This makes a 90° branch and comes in full size or reducing for a straight piece of pipe.

Sockolets are used to connect small-bore socket welding piping to larger size Butt welding Piping Header. The Sockolet is considered a socket weld fitting and is available in Class 3000, 6000, and 9000 for high pressures.

- END – Socket type

- Branch Pipe End – Plain end

- Size Range – 1/2” – 4”

- Most commonly size range used in the industry – 1/2” – 2”, (Safe size range)

- Thickness/Schedule – 3000#, 6000# and 9000# (ratings for socket weld fittings)

A threadolet is the same basic design as a “weldolet.” However, it comes with a threaded end to mate to the branch connection. This makes a 90° branch and comes in full size or reducing for a straight piece of pipe.

The Threadolet is considered a threaded fitting, most commonly available in 3000# and 6000# classifications. Threadolets are used for smaller pipe sizes and low-pressure applications.

- END – Female Threaded

- Branch Pipe End – Male threaded

- Size Range – 1/2” – 2”

- Thickness/Schedule – 2000#, 3000#, and 6000# (ratings for threaded fittings)

Latrolet comes in a 45°or any other special degree as required by the purchaser. Latrolets fittings are available with multi-end connections.

It is available butt-weld to meet specific reinforcement requirements, and 3000# or 6000# classes for Socket Weld and threaded applications.

- END – Female Threaded, Socket Weld, and Bevel end

- Branch Pipe End – Male Threaded, Plain, and Bevel end

- Size Range – 1/2” – 2” NPS (for threaded and socket weld end)

- Size Range – Above 2” NPS (for threaded and socket weld end)

- Thickness/Schedule – 3000# and 6000# (for socket and threaded end) , and for Bevel end thickness will be same as pipe or system rating

- Bevel/butt weld fittings can be used below 2″ NPS (for food, pharma, and corrosive fluid)

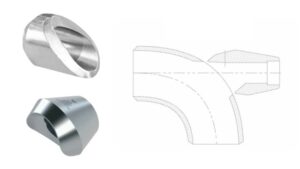

Elbolet is a special type of outlet that fits on the elbow surface. It is most commonly used with 90-degree long radius elbows, options are available for short radius elbows. It comes in different types of ends that suit butt welding, socket welding, and threaded connections in classes 3000# or 6000#.

It typically is used for thermowell and instrumentation connections or as a drain connection when there is too little space for using a Weldolet.

- END – Female Threaded, Socket Weld, and Bevel end

- Branch Pipe or Instrument End – Male Threaded, Plain, and Bevel end

- Size Range – 1/2” – 2” NPS (for threaded and socket weld end)

- Size Range – Above 2” NPS (for threaded and socket weld end)

- Thickness/Schedule – 3000# and 6000# (for socket and threaded end),

- Rating for Buttweld end – same as piping system

Nipolet is a one-piece fitting for valve take-offs, drains, and vents. It is weldolet with an extended pipe body and is available in 90-degree branch connection configurations.

Nipolet comes in different types of ends that suit butt welding, socket welding, or threaded joint. Manufactured in lengths between 3 1/2 to 6 1/2 inches and for XS and XXS schedules.

- END – Female threaded or Socket weld end

- Branch component End – Male threaded or Plain end

- Size Range – 1/2” – 2” (preferred size range)

- Rating – 3000#, 6000#

Sweepolet is a contoured, integrally reinforced, butt-weld branch connection with a low-stress intensification factor for low stresses and long fatigue life. The welded connection on the run pipe side can be easily inspected with the radiographic examination (RX or RT), ultrasounds (UT), and other non-destructive tests.

Sweepolet is used in piping header and pressure vessel when smooth flow transition is necessary and a standard tee cannot be used.

- Where to use – Normally used, if the header is above 24” NPS and Branch is above 8” NPS (It is not fixed, it can vary from company to company)

- It is used for reducing pressure drop and for free-draining of fluid

- Used in radiography requirement

- END – Bevel end

- Branch Pipe End – Bevel end

- Size Range – 8” – 24” (It is mostly used size range)

- Thickness/Schedule – Same as the pipe/Schedule Number

Flangolets are the fittings, which are used for joining large-bore header and flanged end components. The breaker flange can also use joined with Flangolet if the line required frequent maintenance.

- END – Flanged end

- Branch component End – Flanged end

- Size Range – 1/2” – 24” (Normally available)

- Rating – 150#, 300#, 600#, 900#, 1500#

- Flange End preparation- ASME B16.5

Coupolet is Olets with a female NPT thread. Coupolet fittings are similar to thread end half coupling that uses for fire protection sprinkler systems and other low-pressure piping systems.

- END – Female threaded end

- Branch component or fire sprinkler End – Male threaded end

- Size Range – 1/2” – 2” (preferred size range)

- Rating – can be used up-to maximum of 300#

- Thickness/Schedule – 2000# 3000# and 6000#

Major Standards

- MSS-SP-97 – Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends.

- ASME B16.9 – Buttweld Fittings

- ASME B16.11 – Threaded and Socket weld Fittings

- ASME B16.25 – Buttweld/Bevel End Preparation

- ASME B1.20.1 – Thread End Preparation

- ASME B16.5 – Flanged End Fittings

Branch Fittings Materials

We supply a wide range of forged steel materials:

- Carbon steel branch fittings

A105 – For high-temperature Carbon Steel (CS) Olets Fittings

A105: Standard Specification for Carbon Steel Forgings for Piping Applications.

A350 Gr. LF2 – For Low-Temperature Carbon Steel (LTCS)Olets Fittings

A350: Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components. - Stainless steel branch fittings

A182 Gr. F304, A182 Gr. F316, A182 Gr. F321, A182 Gr. F347 – Stainless Steel (SS)

A182: Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service. - Alloy steel branch fittings

A182 Gr. F11, A182 Gr. F22, A182 Gr. F5, A182 Gr. F9, A182 Gr. F91, A182 Gr. F92 – For Low Alloy Steel (LAS)

A182: Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service.

How to Order Branch Fittings?

When you need to buy Sockolets and other branch fittings, please advise the following information:

- Specify Size (Branch & Header)

Header run pipe size (which is generally expressed as a range of possible sizes, for example, 36-22)

Branch pipe size (the NPS of the connecting pipe to the run pipe, for example, 4 inches) - Types of Olets fittings

Llike: Weldolet, Thredolet, Nipolet, Sockolet, etc. - Indicate Rating/Class or Schedule/Pipe Wall

Buttweld-STD, XS, Sch 80, Sch 160/XXS, ect.

Socket weld and NPT threaded-Class 3000 or 6000, etc. - Select Material

Material Grade (example A105, A350 LF2, A182 F304)

Check our latest products