100% Quality Guarantee on All Fittings! Free samples delivery.

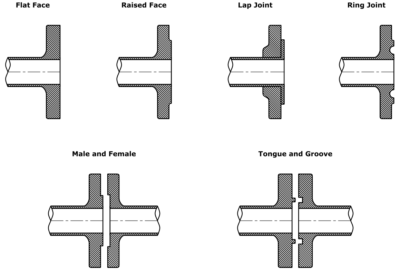

Flange Face Types-RF、FF、RTJ

Flat face flange (FF)

Raised face flange (RF)

Ring joint flange (RTJ)

Male and female flange (M&F)

Large and small tongue-and-groove flange (T&G)

Raised Face (RF)

The Raised Face flange is the most common type used in process plant applications, and is easily to identify. It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face. This face type allows the use of a wide combination of gasket designs, including flat ring sheet types and metallic composites such as spiral wound and double jacketed types.

The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint. Diameter and height are in ASME B16.5 defined, by pressure class and diameter. Pressure rating of the flange determines the height of the raised face.

The typical flange face finish for ASME B16.5 RF flanges is 125 to 250 µin Ra (3 to 6 µm Ra).

Flat Face (FF)

The Flat Face flange has a gasket surface in the same plane as the bolting circle face. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting.

Flat face flanges are never to be bolted to a raised face flange. ASME B31.1 says that when connecting flat face cast iron flanges to carbon steel flanges, the raised face on the carbon steel flange must be removed, and that a full face gasket is required. This is to keep the thin, bittle cast iron flange from being sprung into the gap caused by the raised face of the carbon steel flange.

Ring-Type Joint (RTJ)

The Ring Type Joint flanges are typically used in high pressure (Class 600 and higher rating) and/or high temperature services above 800°F (427°C). They have grooves cut into their faces which steel ring gaskets. The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or Coining) the gasket to make intimate contact inside the grooves, creating a metal to metal seal.

An RTJ flange may have a raised face with a ring groove machined into it. This raised face does not serve as any part of the sealing means. For RTJ flanges that seal with ring gaskets, the raised faces of the connected and tightened flanges may contact each other. In this case the compressed gasket will not bear additional load beyond the bolt tension, vibration and movement cannot further crush the gasket and lessen the connecting tension.

Join or match an RTJ flange with a RF flange?

May I join or match an RTJ flange with a RF flange?. Of course.. that is not allowed.

RTJ flanges have grooves in their sealing faces, while RF flanges do not. If you want to make a connection between the two flanges, you can only apply a flat gasket. This flat gasket wil be make full contact with de sealing surface of the RF flange, but not with the sealing surface of the RTJ flange. Due to the groove in the flange RTJ a certain portion of the gasket is not utilized, and therefore it is not possible to make a properly sealed flange connection. Further, the RTJ flange will be damage the gasket, especially if a spiral wound or metal jacketed gasket is applied.

Never make an RF-RTJ flange connection. Maybe do you have not direct a spill, but when an accident happens, the insurance experts know where they can find you. Consider injuries or fatalities, a wrong flange connection is’t worth it.